Handheld 3D printing for classrooms and makers

Handheld 3D printing brings sketching into the third dimension, letting students and makers turn lines into lightweight structures with a simple motion. With safe materials and clear guidance, it supports art, design, and prototyping in shared spaces.

Across classrooms and maker workshops, compact pens that extrude melted filament are reshaping hands on creativity. These handheld tools bridge drawing and building, allowing users to trace paths in air or on surfaces and assemble models one strand at a time. With low setup overhead and a gentle learning curve, they offer a practical route into spatial reasoning, rapid prototyping, and craft techniques. Choosing materials and settings carefully helps users produce cleaner lines and sturdier joins while maintaining safety for varied age groups.

3D drawing tool: how it works

A 3D drawing tool feeds a thin filament through a heated chamber and out of a small nozzle. As the plastic softens, it can be guided across a surface or lifted to form simple vertical elements. Layers cool and harden quickly, so structures can be built incrementally. Most pens include controls for speed and temperature, allowing users to tune flow for crisp lines or faster fills. Common filaments include PLA and PCL, which are suitable for beginners; ABS is also used but typically demands more ventilation and care due to higher working temperatures.

Good technique begins with stability and planning. Start by sketching outlines on a heat safe mat or paper covered with a protective sheet, then add cross braces and joints before lifting forms into three dimensional shapes. Keep a steady pace to avoid blobs, and pause briefly at corners to ensure tack. For stronger parts, consider adding gussets or doubling back on high stress areas. Let each segment cool before adding the next to maintain alignment and reduce warping.

Handheld 3D printing device in the classroom

In education, a handheld 3D printing device supports STEAM goals by combining visual arts, engineering habits, and problem solving. Learners practice measurement, symmetry, and tolerance while experimenting with structure and balance. Short, focused activities can introduce concepts like support, span, and triangulation. Longer projects may integrate research, sketching, test builds, and reflection journals, reinforcing design thinking from ideation to iteration.

Classroom logistics matter as much as the lesson plan. Establish safety norms such as clear work zones, sleeves rolled up, and no touching the hot end. Younger learners often do well with lower temperature filaments like PCL and pre cut lengths to manage feed more easily. Provide silicone mats, rulers, and templates, and keep small tools such as tweezers and flush cutters handy for trimming strings. Ventilation should be appropriate to the material, and equipment should cool on stands before storage. Rubrics that reward planning, teamwork, and improvement over time help diverse learners succeed.

Creative design pen: projects and tips

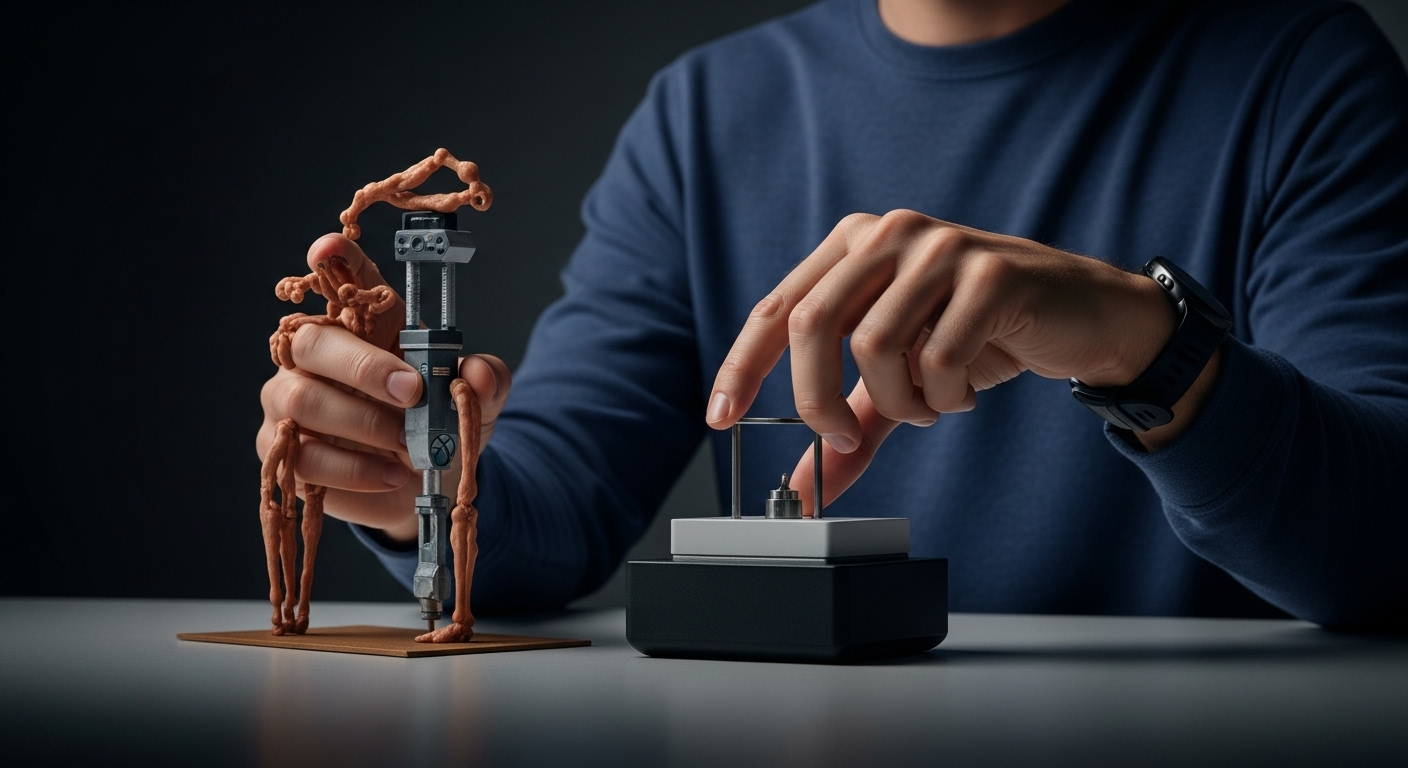

For makers and hobbyists, a creative design pen enables fast exploration before committing to more involved fabrication. Wireframe models are a natural fit, from architectural studies to character maquettes. Stencils help with repeatable parts like gears, brackets, and lattice panels; once printed flat, these elements can be joined into larger assemblies. Hybrid approaches work well too, such as attaching hand drawn ribs to a premade spine or reinforcing a 3D printed shell with hand laid filaments.

Practical tasks extend beyond art. You can create custom cable guides, label holders, jig spacers, and protective bumpers. Small repairs are possible on cracked plastic housings or broken tabs when structural loads are light. For cleaner finishes, trim stray hairs with a warm tip touch or a sharp blade after cooling, then lightly sand. To improve adhesion between parts, roughen contact points and consider a small dab of compatible adhesive. Store filaments in dry containers to reduce brittleness and moisture related bubbling during extrusion.

Materials and ergonomics influence results. PLA tends to hold shape and offers a firm feel, while PCL remains slightly flexible, which can be helpful for wearable or bendable projects. Nozzle size and grip comfort affect precision; a slimmer body and responsive speed control make long sessions less tiring. Some pens accept specialty filaments with wood, metal, or glow additives, which can add texture or visibility for demonstrations. Test new materials on simple shapes first to learn their flow and bonding behavior.

Educators and makers benefit from a gradual skill ramp. Begin with tracing and flat assemblies, move to simple frames and boxes, then attempt curves, domes, and jointed mechanisms. Encourage drafting reference lines and using lightweight jigs such as cardboard forms or foam blocks to hold angles while pieces set. Documenting attempts with photos and notes helps users connect causes and effects, like how speed, temperature, and travel path alter surface quality and strength.

Environmental considerations are part of responsible use. Favor materials suited to your space and age group, and collect offcuts for art collages or future testing instead of discarding them. Durable projects that teach core concepts tend to provide more value than high volume output. With sensible maintenance, pens last longer and produce better results; keep nozzles clean, unload filament at the end of sessions, and store devices where they cannot be knocked over while cooling.

Conclusion Handheld 3D printing complements both structured lessons and open ended experimentation. When matched with suitable materials, clear safety routines, and thoughtful project design, these compact tools help learners and makers translate ideas into tangible forms. The approach encourages iteration, dexterity, and visual reasoning, building confidence while revealing how form and function meet in three dimensions.