Thermal plastic modeling in real-time applications

Thermal plastic modeling has evolved from industrial manufacturing processes into accessible creative tools that anyone can use at home or in professional settings. By heating and shaping plastic materials in real time, artists, designers, educators, and hobbyists can transform digital concepts into tangible three-dimensional forms. This technology bridges the gap between imagination and physical reality, offering immediate feedback and hands-on control that traditional manufacturing methods cannot match.

The ability to create three-dimensional objects on demand has revolutionized how people approach design, prototyping, and artistic expression. Thermal plastic modeling technologies allow users to work with heated materials that solidify quickly, enabling rapid iteration and experimentation. Unlike conventional manufacturing that requires molds, machinery, or lengthy production cycles, real-time thermal plastic modeling puts creative control directly in the hands of the user. This approach has found applications across education, product development, art installations, and therapeutic activities.

How Does Drawing in Three Dimensions Work?

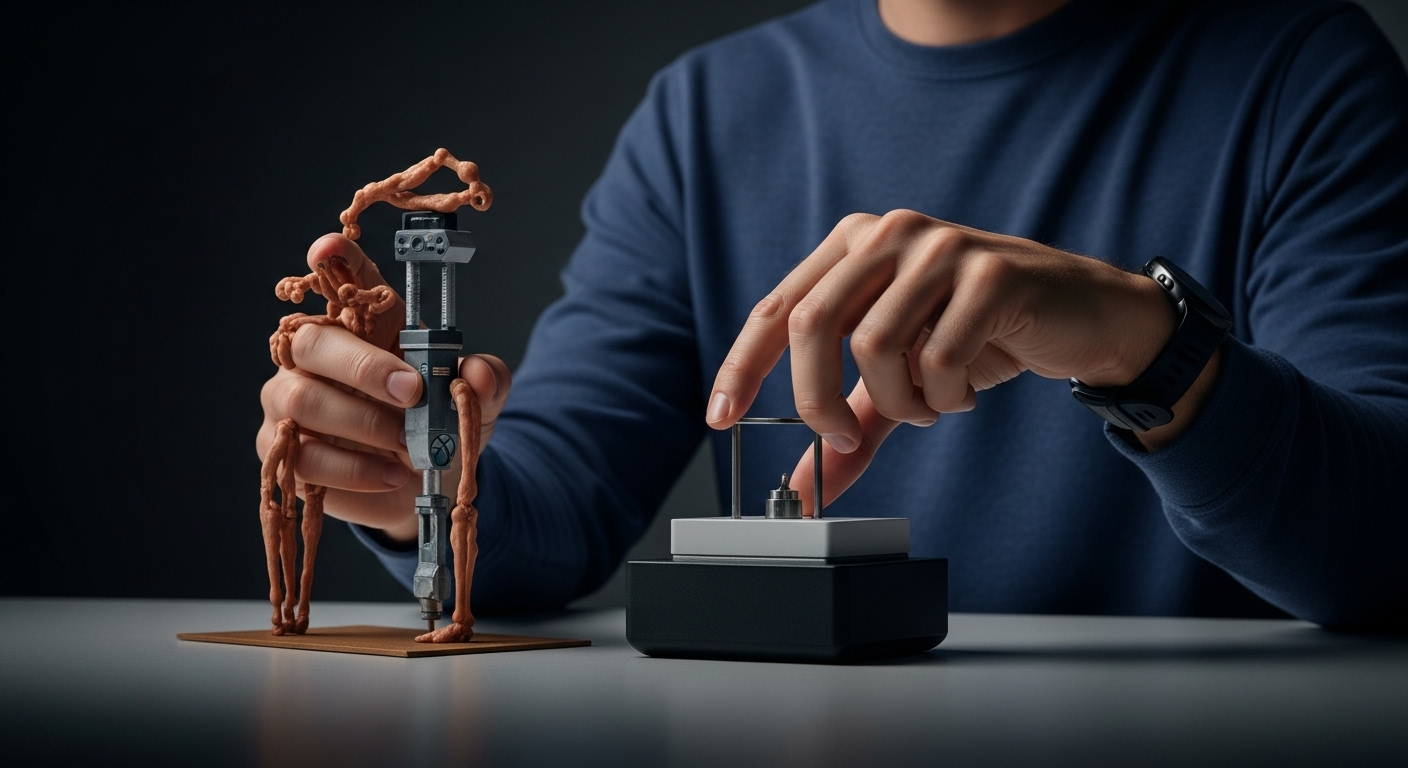

A 3D pen lets you draw objects in three dimensions instead of on flat paper. Unlike traditional drawing tools that leave marks on a surface, these devices build structures layer by layer in open space. Users can create freestanding sculptures, decorative items, architectural models, and functional prototypes without needing computer software or complex machinery. The process requires steady hand control and spatial awareness, as the material must be guided precisely to form the intended shape. Beginners typically start with simple geometric forms before progressing to more intricate designs. The learning curve varies depending on artistic background and manual dexterity, but most users achieve basic competency within a few hours of practice.

What Is the Technology Behind Heated Extrusion?

It works by melting plastic filament and extruding it through a heated tip. The device contains a heating element that raises the temperature of solid plastic material to its melting point, typically between 160 and 240 degrees Celsius depending on the material type. Once liquefied, the plastic is pushed through a narrow nozzle by a motorized feed mechanism. As the molten material exits the tip, it begins cooling immediately upon contact with air, solidifying within seconds. This rapid phase transition allows users to build vertical structures and create overhanging features without additional support. Temperature control is essential for achieving consistent flow rates and preventing clogs or material degradation.

How Quickly Can Ideas Become Physical Objects?

A 3D pen turns creative ideas into physical shapes instantly. The immediacy of this process distinguishes thermal plastic modeling from other fabrication methods that involve design software, file preparation, and automated production cycles. Users can sketch a concept and hold a tangible version within minutes, making iterative design extremely efficient. This rapid prototyping capability proves valuable in educational settings where students benefit from immediate visual and tactile feedback. Artists appreciate the spontaneity and organic quality that hand-guided extrusion provides compared to machine-generated precision. The direct connection between mental visualization and physical creation fosters a unique creative flow that many users find more intuitive than digital modeling interfaces.

What Materials Are Compatible with Thermal Plastic Modeling?

The most common materials used in handheld thermal plastic modeling are polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). PLA is derived from renewable resources like cornstarch or sugarcane and melts at lower temperatures, making it safer and more pleasant to work with due to minimal odor. ABS is a petroleum-based plastic that requires higher temperatures and produces more noticeable fumes, but offers greater durability and heat resistance in finished objects. Some advanced devices also accommodate specialty filaments including flexible thermoplastic polyurethane (TPU), wood-infused composites, metal-filled variants, and glow-in-the-dark formulations. Material choice affects not only the working experience but also the mechanical properties, appearance, and longevity of completed projects.

What Are Practical Applications Across Different Fields?

Thermal plastic modeling serves diverse purposes across education, professional design, artistic creation, and therapeutic intervention. In classrooms, teachers use these tools to make abstract concepts tangible, helping students visualize mathematical principles, molecular structures, and historical artifacts. Product designers create rapid prototypes to test form factors and ergonomics before committing to expensive manufacturing processes. Artists incorporate the medium into mixed-media installations, jewelry fabrication, and sculptural works. Occupational therapists employ thermal plastic modeling to improve fine motor skills and hand-eye coordination in rehabilitation settings. Hobbyists repair household items, customize accessories, and create personalized gifts. The versatility of real-time thermal plastic modeling continues to expand as users discover novel applications.

What Should Users Consider Regarding Cost and Equipment Options?

Entry-level thermal plastic modeling devices typically range from 20 to 50 USD, while professional-grade models with advanced temperature controls and interchangeable nozzles can cost between 80 and 200 USD. Material costs vary based on filament type and quality, with standard PLA and ABS spools (usually containing 10 to 15 meters) priced between 5 and 15 USD. Specialty filaments with unique properties or colors may cost 15 to 30 USD per spool. Additional accessories such as silicone finger protectors, cutting tools, and stencil templates add 10 to 40 USD to initial setup costs. When evaluating options, users should consider nozzle diameter (affecting detail level), temperature range (determining material compatibility), and ergonomic design (impacting comfort during extended use).

| Device Category | Typical Price Range | Key Features | Material Compatibility |

|---|---|---|---|

| Basic Entry Models | 20-50 USD | Single temperature setting, basic controls | PLA only |

| Mid-Range Devices | 50-100 USD | Adjustable temperature, LCD display, speed control | PLA, ABS |

| Professional Tools | 100-200 USD | Precise temperature control, multiple nozzles, ergonomic design | PLA, ABS, TPU, specialty filaments |

| Filament Materials | 5-30 USD per spool | Varies by type and quality | Depends on device specifications |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

What Are the Limitations and Safety Considerations?

While thermal plastic modeling offers significant creative freedom, users must understand its constraints and safety requirements. The heated nozzle reaches temperatures that can cause burns, requiring careful handling and supervision when children are involved. Adequate ventilation is necessary when working with certain materials, particularly ABS, which releases potentially irritating fumes. The manual nature of the process limits the precision achievable compared to computer-controlled manufacturing, making it less suitable for applications requiring exact tolerances. Structural strength of hand-drawn objects varies considerably based on technique, with poorly fused layers creating weak points. Material waste can accumulate during the learning process as users refine their skills. Despite these considerations, proper technique and reasonable precautions allow safe and productive use across age groups and skill levels.

Thermal plastic modeling in real-time applications represents a democratization of three-dimensional fabrication technology. By removing barriers associated with traditional manufacturing and digital design software, these tools empower individuals to explore spatial creativity and practical problem-solving. As materials science advances and device capabilities expand, the applications for immediate thermal plastic modeling will continue to grow across educational, professional, and recreational contexts. The tactile and visual immediacy of this medium offers unique advantages that complement rather than replace other fabrication technologies, securing its place in the evolving landscape of personal manufacturing and creative expression.